Paipu Laina Kila Kalapona API 5L Gr. B/X42 /X52 /X60 /X65 Psl2

| Nā Papa | API 5L Papa B, X42, X52, X56, X60, X65, X70, X80 |

| Pae Kikoʻī | PSL1, PSL2 |

| Ka laulā o ke anawaena waho | 1/2” a i 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 ʻīniha, 18 ʻīniha, 20 ʻīniha, 24 ʻīniha a hiki i 40 ʻīniha. |

| Papa Kuhikuhi Mānoanoa | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, a i SCH 160 |

| Nā ʻAno Hana Hana | ʻAʻohe ʻōwili (ʻōwili wela a ʻōwili anu), Welded ERW (welded pale uila), SAW (Welded Arc Submerged) ma LSAW, DSAW, SSAW, HSAW |

| ʻAno Hoʻopau | Nā wēlau Beveled, Nā wēlau Plain |

| Ka laulā lōʻihi | SRL (Lōʻihi Random Hoʻokahi), DRL (Lōʻihi Random Pālua), 20 FT (6 mika), 40FT (12 mika) a i ʻole, i hoʻopilikino ʻia |

| Nā pāpale palekana | palaki a hao paha |

| Ka mālama ʻana i ka ʻili | ʻAno maoli, Varnished, Pena ʻEleʻele, FBE, 3PE (3LPE), 3PP, CWC (Uhi ʻia me ke Kaumaha Konikete) CRA Clad a i ʻole Lined |

ʻO ka paipu API 5L e pili ana i ka paipu kila kalapona i hoʻohana ʻia i nā ʻōnaehana hoʻoili aila a me ke kinoea. Hoʻohana ʻia nō hoʻi ia e halihali i nā wai ʻē aʻe e like me ka mahu, ka wai, a me ka lepo.

Uhi ka kikoʻī API 5L i nā ʻano hana wili ʻia a me nā ʻano hana seamless.

Nā ʻAno i Welded ʻia: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

ʻO nā ʻano maʻamau o ka paipu welded API 5L e like me kēia:

ERWHoʻohana ʻia ka kuʻihao kū'ē uila no ka paipu me ke anawaena ma lalo o 24 ʻīniha.

ʻIke/ ʻIkeʻO ka hoʻoheheʻe ʻāʻī submerged pālua ʻaoʻao/hoʻoheheʻe ʻāʻī submerged kekahi ʻano hana hoʻoheheʻe hiki ke hoʻohana ʻia ma kahi o ERW no ka paipu anawaena nui.

LSAWʻO ka longitudinal submerged Arc welding i hoʻohana ʻia no ka paipu a hiki i 48 ʻīniha ke anawaena. Ua ʻike ʻia ʻo ke kaʻina hana JCOE.

SSAW/HSAW: Kuʻihao ʻāʻī wili i lalo o ka wai/kuʻihao ʻāʻī wili i lalo o ka wai me ke anawaena o ka paipu a hiki i 100 ʻīniha.

Nā ʻAno Paipu Seamless: Paipu Seamless ʻōwili wela a me ka Paipu Seamless ʻōwili anu

Hoʻohana pinepine ʻia ka paipu humuhumu ʻole no nā paipu liʻiliʻi ke anawaena (ʻoi aku ka liʻiliʻi ma mua o 24 ʻīniha).

(ʻOi aku ka hoʻohana ʻia ʻana o ka paipu kila humuhumu ʻole ma mua o ka paipu i hoʻopili ʻia no nā anawaena paipu ma lalo o 150 mm (6 ʻīniha).

Hāʻawi pū mākou i nā paipu wili ʻole nui. Ma ka hoʻohana ʻana i ke kaʻina hana ʻōwili wela, hiki iā mākou ke hana i nā paipu wili ʻole a hiki i ka 20 ʻīniha (508 mm) ke anawaena. Inā makemake ʻoe i nā paipu wili ʻole i ʻoi aku ma mua o 20 ʻīniha ke anawaena, hiki iā mākou ke hana iā ia me ka hoʻohana ʻana i ke kaʻina hana hoʻonui wela a hiki i ka 40 ʻīniha (1016 mm) ke anawaena.

Hoʻākāka ka API 5L i nā māka aʻe: Papa B, X42, X46, X52, X56, X60, X65, X70, a me X80.

Nui nā ʻano kila like ʻole no ka paipu kila API 5L e like me ka Papa B, X42, X46, X52, X56, X60, X65, X70, a me X80. Me ka hoʻonui ʻia ʻana o ka papa kila, ʻoi aku ka paʻa o ka mana like kalapona, ʻoi aku ka kiʻekiʻe o ka ikaika mechanical.

Eia kekahi, ʻaʻole like ka hoʻohuihui kemika o nā paipu API 5L seamless a me nā paipu welded no kahi papa kikoʻī, ʻoi aku ka nui o nā koi o ka paipu welded a me ka nui o ke kalapona a me ka sulfur.

Ka Hoʻohui Kemika no ka paipu PSL 1 me t ≤ 0.984” | |||||||

| Papa kila | ʻĀpana nuipa, % ma muli o ka wela a me nā loiloi huahana a,g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| ʻoi loa b | ʻoi loa b | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | |

| Paipu humuhumu ʻole | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Paipu i hoʻopaʻa ʻia | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; a me Mo ≤ 0.15%, | |||||||

| b. No kēlā me kēia hōʻemi ʻana o 0.01% ma lalo o ka nui kiʻekiʻe i kuhikuhi ʻia no ke kalapona, ʻae ʻia ka hoʻonui ʻana o 0.05% ma luna o ka nui kiʻekiʻe i kuhikuhi ʻia no Mn, a hiki i ka nui o 1.65% no nā papa ≥ L245 a i ʻole B, akā ≤ L360 a i ʻole X52; a hiki i ka nui o 1.75% no nā papa > L360 a i ʻole X52, akā < L485 a i ʻole X70; a hiki i ka nui o 2.00% no ka papa L485 a i ʻole X70., | |||||||

| c. Inā ʻaʻole i ʻaelike ʻia NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Ke ʻole i ʻaelike ʻia., | |||||||

| f. Inā ʻaʻole i ʻaelike ʻia, NB + V = Ti ≤ 0.15%, | |||||||

| g. ʻAʻole ʻae ʻia ka hoʻohui ʻana o B me ka manaʻo hoʻokahi a ʻo ke koena B ≤ 0.001% | |||||||

| Ka Hoʻohui Kemika no ka paipu PSL 2 me t ≤ 0.984” | |||||||||||||||||||||

| Papa kila | ʻĀpana nuipa, % ma muli o ka wela a me nā loiloi huahana | Kālepa like me a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | ʻĒ aʻe | CE IIW | CE Pcm | |||||||||||

| ʻoi loa b | ka nui loa | ʻoi loa b | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ||||||||||||

| Paipu humuhumu a me ka Welded | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | E like me ka ʻaelike | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | ʻo wau,j | E like me ka ʻaelike | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | E like me ka ʻaelike | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | E like me ka ʻaelike | |||||||||||

| Paipu i hoʻopaʻa ʻia | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | ʻo wau,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ʻo wau,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | ʻo wau,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, e like me ka ʻaelike nā palena CE. ʻO nā palena CEIIW i hoʻopili ʻia ma C > 0.12% a pili nā palena CEPcm inā C ≤ 0.12%, | |||||||||||||||||||||

| b. No kēlā me kēia hōʻemi ʻana o 0.01% ma lalo o ka palena kiʻekiʻe i kuhikuhi ʻia no C, ʻae ʻia ka hoʻonui ʻana o 0.05% ma luna o ka palena kiʻekiʻe i kuhikuhi ʻia no Mn, a hiki i ka palena kiʻekiʻe o 1.65% no nā māka ≥ L245 a i ʻole B, akā ≤ L360 a i ʻole X52; a hiki i ka palena kiʻekiʻe o 1.75% no nā māka > L360 a i ʻole X52, akā < L485 a i ʻole X70; a hiki i ka palena kiʻekiʻe o 2.00% no nā māka ≥ L485 a i ʻole X70, akā ≤ L555 a i ʻole X80; a hiki i ka palena kiʻekiʻe o 2.20% no nā māka > L555 a i ʻole X80., | |||||||||||||||||||||

| c. Inā ʻaʻole i ʻaelike ʻia Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Inā ʻaʻole i ʻae ʻia, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% a me Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Inā ʻaʻole i ʻaelike ʻia, | |||||||||||||||||||||

| g. Inā ʻaʻole i ʻaelike ʻia, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Inā ʻaʻole i ʻae ʻia, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% a me MO ≤ 0.50%, | |||||||||||||||||||||

| i. Inā ʻaʻole i ʻae ʻia, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% a me MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Inā ʻaʻole i ʻae ʻia, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% a me MO ≤ 0.80%, | |||||||||||||||||||||

| l. No nā papa paipu PSL 2 āpau koe wale nō kēlā mau papa me nā memo wāwae j i ʻōlelo ʻia, pili kēia. Inā ʻaʻole i ʻae ʻia, ʻaʻole ʻae ʻia ka hoʻohui manaʻo o B a ʻo ke koena B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Kūlana Hoʻouna | Papa paipu |

| PSL1 | E like me ka ʻōwili ʻia, hoʻonohonoho maʻamau, hoʻonohonoho maʻamau i hoʻokumu ʻia | A |

| ʻO ka ʻōwili like ʻana, ka ʻōwili normalizing, ka ʻōwili thermomechanical, ka hoʻokumu thermo-mechanical, ka hoʻokumu normalizing, ka hoʻonohonoho normalized, ka hoʻonohonoho normalized a me ka hoʻohaʻahaʻa ʻia a i ʻole inā ʻae ʻia Q&T SMLS wale nō | B | |

| E like me ka ʻōwili ʻia, hoʻonohonoho ʻia i ʻōwili ʻia, ʻōwili thermomechanical, hoʻokumu ʻia thermo-mechanical, hoʻonohonoho ʻia i hoʻokumu ʻia, hoʻonohonoho ʻia, hoʻonohonoho ʻia a hoʻomaʻamaʻa ʻia | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | E like me ka ʻōwili ʻia | BR, X42R |

| Hoʻomaʻamaʻa ʻana i ʻōwili ʻia, hoʻomaʻamaʻa ʻana i hoʻokumu ʻia, hoʻomaʻamaʻa ʻia a i ʻole hoʻomaʻamaʻa ʻia a hoʻoikaika ʻia | BN, X42N, X46N, X52N, X56N, X60N | |

| Ua pio a hoʻomāmā ʻia | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| ʻOwili ʻia ka thermomechanical a i ʻole i hoʻokumu ʻia ka thermomechanical | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| ʻōwili ʻia ka Thermomechanical | X90M, X100M, X120M | |

| ʻO ka lawa (R, N, Q a i ʻole M) no nā māka PSL2, no ke kila kila |

He ʻokoʻa ka PSL1 a me PSL2 ma ke ʻano o ka hoʻāʻo ʻana a me ko lākou mau waiwai kemika a me nā ʻano mechanical.

ʻOi aku ka paʻakikī o ka PSL2 ma mua o ka PSL1 ma ka hoʻohui kemika, nā waiwai tensile, ka hoʻāʻo hopena, ka hoʻāʻo ʻole e luku a pēlā aku.

Hoʻāʻo hopena

ʻO PSL2 wale nō ke koi nei i ka hoʻāʻo hopena: koe wale nō ʻo X80.

NDT: Hoʻāʻo ʻAʻole Luku. ʻAʻole koi ʻo PSL1 i ka hoʻāʻo ʻana ʻaʻole luku inā pili ka hoʻāʻo ʻana ʻaʻole luku. Hana ʻo PSL2.

(Hoʻāʻo ʻole luku: Hoʻohana ka hoʻāʻo ʻole luku a me ka hoʻāʻo ʻana ma ke kūlana API 5L i ka radiographic, ultrasonic, a i ʻole nā ʻano hana ʻē aʻe (me ka ʻole o ka luku ʻana i ka mea) e ʻike i nā hemahema a me nā hemahema i nā pipelines.)

ʻO ka hoʻopili ʻanaʻōlohelohe ma ke ʻano laulā, hoʻopaʻa uea kila, loaikaika.

Inā he mau koi kūikawā kāu, hiki iā ʻoe ke hoʻohanaʻōpala pale ʻino, a ʻoi aku ka nani.

Nā hana palekana no ka hoʻopili ʻana a me ka lawe ʻana i nā paipu kila kalapona

1.Paipu kila API 5Lpono e pale ʻia mai ka pōʻino i hana ʻia e ke kuʻi ʻana, ka extrusion a me nā ʻoki i ka wā o ka halihali, ka mālama ʻana a me ka hoʻohana ʻana.

2. I ka wā e lawelawe ai i nā paipu kila kalapona, pono ʻoe e makaʻala i ka pahū ʻana, ke ahi, ka lāʻau make a me nā ulia ʻē aʻe, a e hahai i nā kaʻina hana palekana.

3. I ka wā e hoʻohana ai,Paipu API 5L kila kalaponapono e pale i ka hoʻopili ʻana me nā mahana kiʻekiʻe, nā mea ʻino, a pēlā aku. Inā hoʻohana ʻia ma kēia mau wahi, pono e koho ʻia nā paipu kila kalapona i hana ʻia me nā mea kūikawā e like me ke kūpaʻa wela kiʻekiʻe a me ke kūpaʻa i ka pala.

4. Pono ke koho ʻana o ka paipu kila kalapona i nā mea kūpono a me nā kikoʻī e like me nā mea āpau e pili ana i ke kaiapuni hoʻohana, ke ʻano waena, ke kaomi, ka mahana a pēlā aku.

5. Pono e hana ʻia nā nānā a me nā hoʻāʻo e pono ai ma mua o ka hoʻohana ʻia ʻana o ka paipu kila kalapona e hōʻoia i kona kūlana maikaʻi.

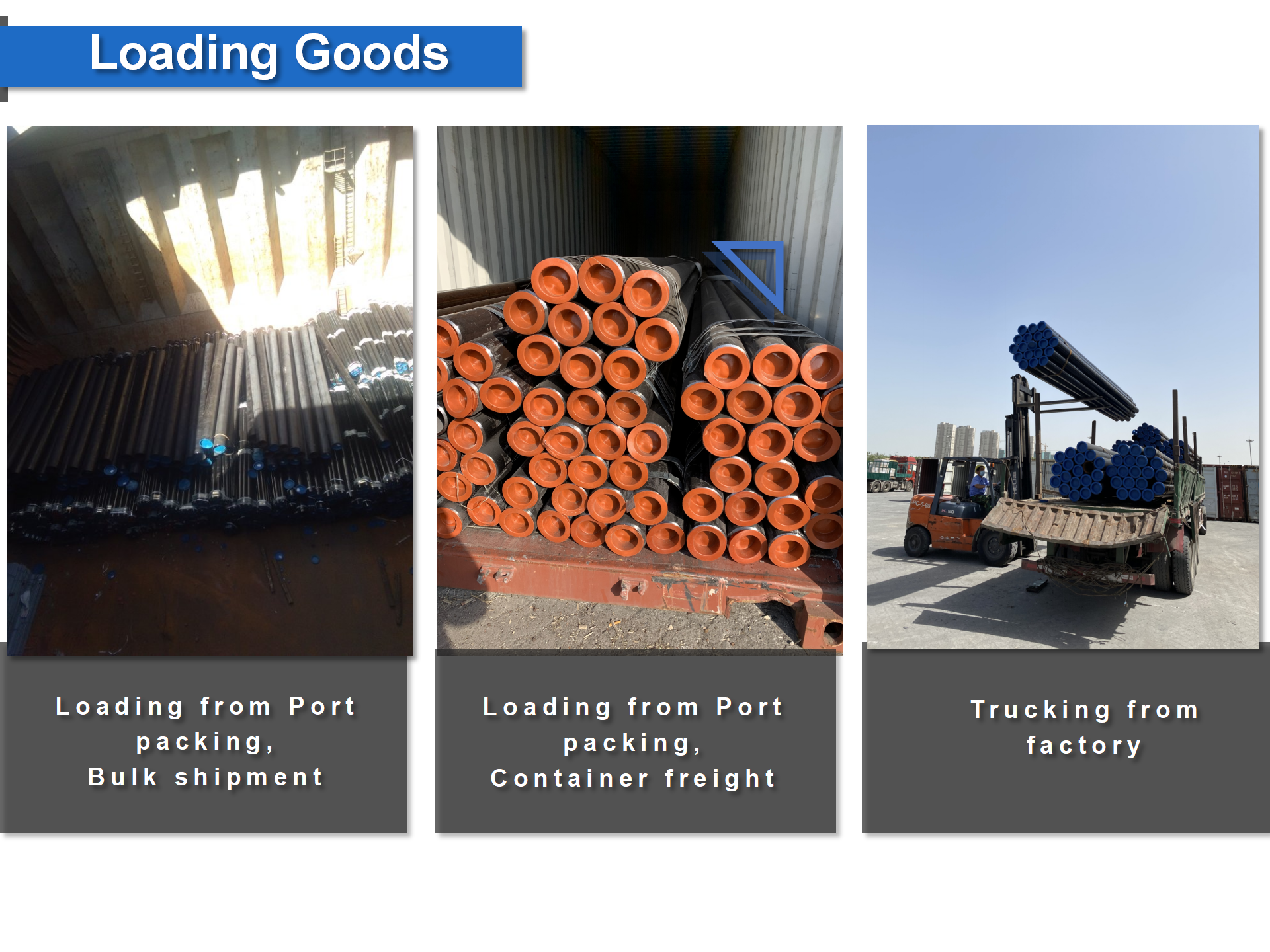

Ka halihali:Hoʻouna wikiwiki (Laʻana), Ea, Kaʻaahi, ʻĀina, Hoʻouna kaiFCL a i ʻole LCL a i ʻole Bulk)

Q: He mea hana ua?

A: ʻAe, ʻo mākou ka mea hana paipu kila wili e waiho ana ma ke kauhale ʻo Daqiuzhuang, ke kūlanakauhale ʻo Tianjin, Kina

Q: Hiki iaʻu ke kauoha hoʻokolokolo i kekahi mau tona wale nō?

A: ʻAe. Hiki iā mākou ke hoʻouna i ka ukana nou me ka lawelawe LCL. (ʻUmi ka ukana ipu)

Q: Inā hāpana manuahi?

A: Laʻana manuahi, akā uku ka mea kūʻai no ka ukana.

Q: ʻO ʻoe anei ka mea hoʻolako gula a hana i ka hōʻoia kālepa?

A: He 13 mau makahiki mākou i mea hoʻolako gula a ʻae i ka hōʻoia kālepa.